ProFlow Mixer – KMPF

Legacy, turned legendary.

Our ProFlow range of mixers is 30 years of mixing experience, packaged in a robust, sustainable and user-friendly product. Everything from its energy efficient motor, the mixing head design, the bearing materials and its many components is built for one thing: perfect flow. Every day.

The best mixer we ever built: meet the ProFlow

The ProFlow Mixer is a bottom mounted magnetically coupled mixer with a unique mix of intelligent controls, user-friendly design and innovative engineering. Its unique design and many powerful features provide cost efficient, low maintenance mixing processes with reliable mixing results.

Take advantage of full product recovery

The unique mixing head design and the position of the blades close to the bottom of the tank allows the mixer to run while the tank is being emptied. Mixing to the last drop with uncompromised cleanability.

Due to the low building height of the mixer head along with a lot of wing area close to the bottom the mixer is excellent in handling continues mixing of low levels as well.

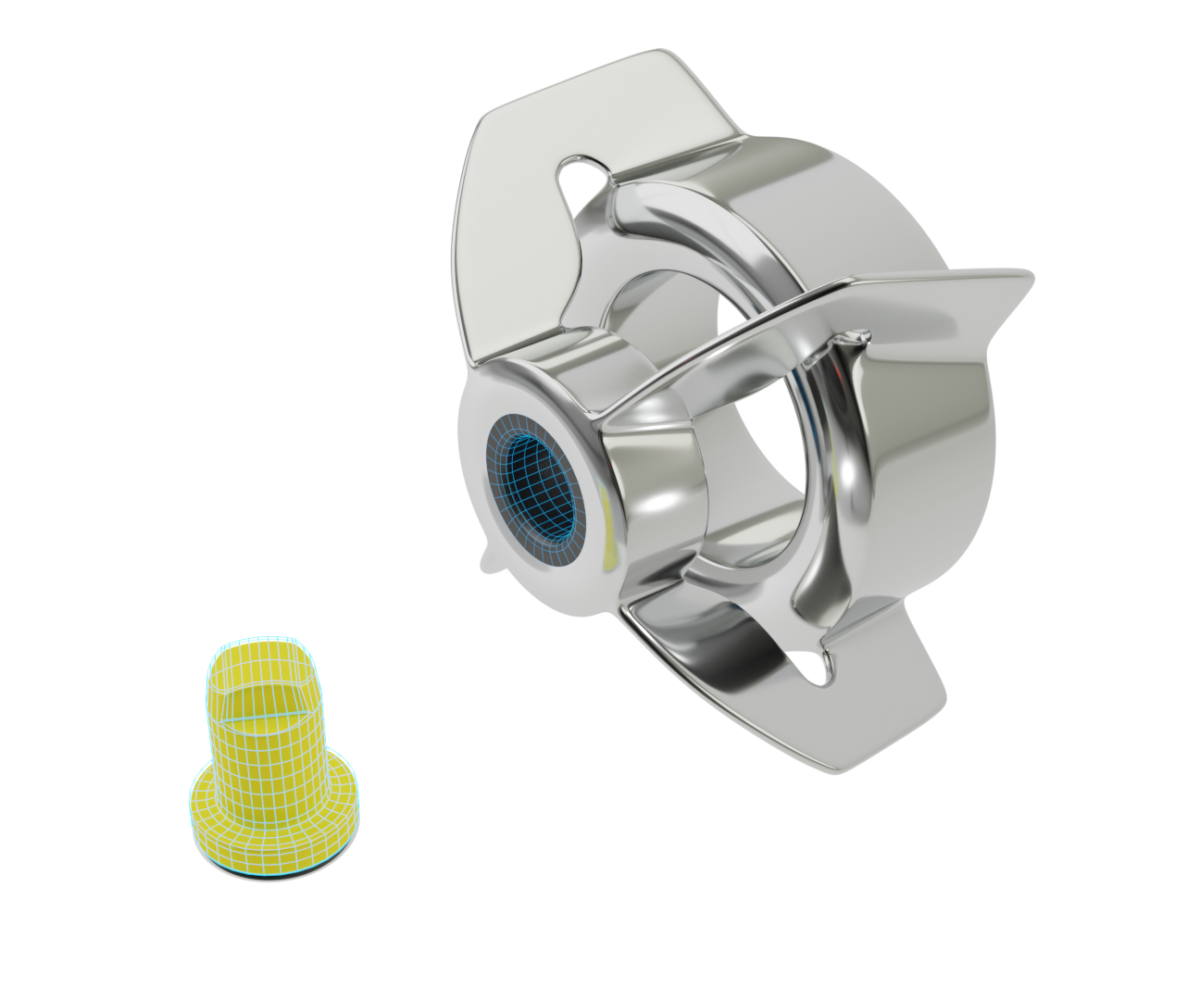

Robust bearing – ZERO particle shedding

The robust bearing combination of Zirconium Oxide (ZrO2) and Silicon Carbide (SiC) and the fine-tuned geometry, ensures no particle shedding in your media. The higher bending strength of the Zirconium Oxide material enabled us to do the male bearing in one solid piece, this optimizes the aseptic design and increase the robustness and low wear property. The particle shedding test was done by the independent research institute RISE in Sweden according to USP<788> PARTICULATE MATTER IN INJECTIONS, no particles could be detected.

Total integrity of the tank

The Kest Mixer Tank plate is machined from a solid bar. The design is FEM analyzed to comply with PED and ASME pressure vessel code. The Tank Plate is welded into the tank and creates a solid barrier with no risk of allowing contamination of the media inside the tank.

Ensure cleanroom optimized mixing

The ProFlow drive unit operates completely without fans and is fully encapsulated in a smooth hygienic cover. This makes the ProFlow very easy to keep free from dust and particles and allows for undisturbed laminar air flow in your clean room.

Contribute to a better environment

When we started to develop the ProFlow mixer line, one of the most important goals was to decrease power consumption. The ProFlow mixing line is equipped with a very efficient DC motor, controlled with smart electronics that can reduce the energy consumption up to 80 percent. This will cut cost on your energy bill and substantially contribute to a better environment at the same time. Read the complete test report.

Except from that we gained several other positive effects, low heat generation that eliminated the need of any fans or other cooling system – this enabled an aseptic design of the drive unit. The low heat generation is also essential to some of our customers heat sensitive projects.

Control everything, in real time

The ProFlow is equipped with a range of innovative electronics, monitoring capabilities and intelligent control logic. This gives you maximum process control, unparalleled energy efficiency and minimal heat transfer.

The integrated speed sensor system can detect if the mixing head is mounted in the tank, the rotation speed of the mixing head and the rotation direction. The signals can conveniently be monitored on the units LED’s and are delivered through the multi cable for integration in your automation system.

The rotation speed is controlled by sending 0-10 Volt DC into the unit, so there is no need for a variable frequency drive (VFD).

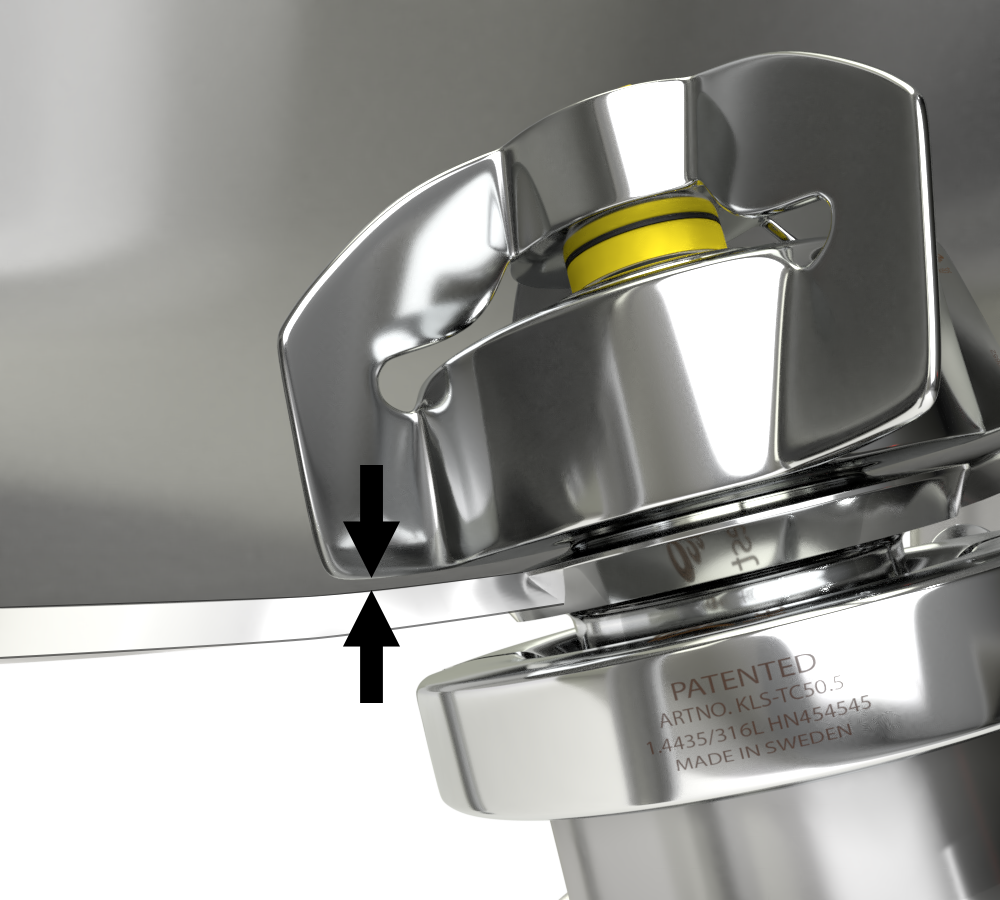

Minimize downtime

The drive unit is equipped with our patented Kest-Lock connection that ensures quick disconnection from the tank plate during maintenance. When you put the drive unit back on the tank plate, the spring closed Kest-Lock helps the operator to hold the drive unit in place when tightening the screw to lock it in place.

Technical specifications

- The range covers up to 1200 Liters

- Reduces energy consumption with up to 80%

- All tank plates are FEM analyzed according to PED and ASTM

- Welding tool available (recommended)

- Full traceability on all parts in media contact

- 3.1 material certificate on all parts in media contact

- Elastomers approved acc. FDA regulation CFR 177.2600, USP Class VI

Technical specifications

30 Liter (at viscosity 1 cP)

8 Gallon (at viscosity 1 cP)

See selection guide on data sheet for correct sizing of the mixer

1 - 800 cP

50 - 680 RPM

Inside tank

Design Temperature 0°C to +150°C / +32°F to +302°F

Operating temperature 0°C to +135°C / +32°F to +275°F

Outside tank

0°C to +40°C / +32°F to +104°F

63 W

2.5 kg

5.5 lb

24 VDC

3.5 A

70 Liter (at viscosity 1 cP)

18.5 Gallon (at viscosity 1 cP)

See selection guide on data sheet for correct sizing of the mixer

1 - 800 cP

50 - 490 RPM

Inside tank

Design Temperature 0°C to +150°C / +32°F to +302°F

Operating temperature 0°C to +135°C / +32°F to +275°F

Outside tank

0°C to +40°C / +32°F to +104°F

63 W

3.0 kg

6.6 lb

24 VDC

3.5 A

200 Liter (at viscosity 1 cP)

53 Gallon (at viscosity 1 cP)

See selection guide on data sheet for correct sizing of the mixer

1 - 800 cP

50 - 490 RPM

Inside tank

Design Temperature 0°C to +150°C / +32°F to +302°F

Operating temperature 0°C to +135°C / +32°F to +275°F

Outside tank

0°C to +40°C / +32°F to +104°F

63 W

3.5 kg

7.7 lb

24 VDC

3.5 A

700 Liter (at viscosity 1 cP)

185 Gallon (at viscosity 1 cP)

See selection guide on data sheet for correct sizing of the mixer

1 - 800 cP

50 - 490 RPM

Inside tank

Design Temperature 0°C to +150°C / +32°F to +302°F

Operating temperature 0°C to +135°C / +32°F to +275°F

Outside tank

0°C to +40°C / +32°F to +104°F

754 W

6.2 kg

13.7 lb

48 VDC

18 A

1200 Liter (at viscosity 1 cP)

317 Gallon (at viscosity 1 cP)

See selection guide on data sheet for correct sizing of the mixer

1 - 800 cP

50 - 490 RPM

Inside tank

Design Temperature 0°C to +150°C / +32°F to +302°F

Operating temperature 0°C to +135°C / +32°F to +275°F

Outside tank

0°C to +40°C / +32°F to +104°F

754 W

6.4 kg

14.1 lb

48 VDC

18 A

Talk to an expert!

Do you need assistance to find the best fit for your application? Or do you need some customization? Talk directly with one of our engineers – we are here to help!

Other mixers

Learn more about the other products in our range